Ever growing advances in expertise and steady course of optimization strategies have helped be certain that the worldwide provide chain runs effectively, turning uncooked supplies into merchandise that make their approach to bodily shops and ecommerce warehouses. Nevertheless, we’ve witnessed how an out of doors disturbance like a pandemic or flood can fracture the availability chain, throwing companies and customers into short-term chaos. These disruptions are usually not essentially as a consequence of an absence of product however extra so to an absence of knowledge. The place are the merchandise throughout the provide chain at any given second? How can they get to their vacation spot when wanted? When are there spikes in shopper demand and the way rather more of a product might be wanted to fulfill that demand?

High quality is one other vital side of producing. Whether or not you’re speaking about elements on a high-speed manufacturing line or ranges in filling machines, each side of the manufacturing trade focuses on high quality detection and high quality assurance. Sustaining prime quality is troublesome, even for skilled operators.

Producers have to run their companies out of the windshield, not the rearview mirror. A pc imaginative and prescient platform gives the flexibility to “see” and interpret in near-real time by gathering knowledge on the edge and analyzing it on the proper velocity and velocity to make time-critical determinations and agile enterprise selections.

This forward-looking functionality offered by laptop imaginative and prescient is enabling manufacturing organizations to higher tackle these prime 5 enterprise wants:

1. How can we enhance manufacturing personnel and facility security?

For personnel, cameras search for private protecting tools (PPE) use, corresponding to arduous hats and security glasses, after which the system both sends alerts to a supervisor if PPE will not be being worn or retains monitor of metrics {that a} security officer makes use of to find out whether or not coaching is required. Geofencing creates a digital boundary round tools that’s scorching to the contact or an space inside attain of a robotic; a loud alarm or flashing mild is triggered when an individual or object will get too shut.

Repetitive actions is one other security challenge that has lengthy been a bane of producing processes. A number of repetitions of the identical motion, corresponding to when assembling a circuit board, may cause accidents in employees. Utilizing cameras to check and optimize workflows typically reduces the incidence of worker accidents, selling an general safer office.

Using thermal cameras in manufacturing can also be on the rise to observe objects for which sensors are usually not sensible or to look at objects which might be difficult for individuals to entry in situ. For instance, you may practice a digital camera on conveyer system bearings to observe the change in temperature, finally producing a temperature histogram that reveals the warmth signature over time which will point out a future failure. Thermography can also be useful if visibility is required in low mild, corresponding to for perimeter safety in poorly lit areas.

2. How can we improve manufacturing operational efficiencies right now and what can we count on sooner or later?

Operational effectivity usually comes all the way down to general tools effectiveness. When you’re not producing a top quality product, you both should throw it away or carry out rework. A rise in manufacturing is required to make up for off-spec merchandise to fulfill the product demand plan.

Think about a manufacturing line that makes use of automation expertise, corresponding to programmable logic controllers (PLCs). Cameras could also be used to seize real-time streaming video photographs and thermal imagery of the manufacturing line and tools.

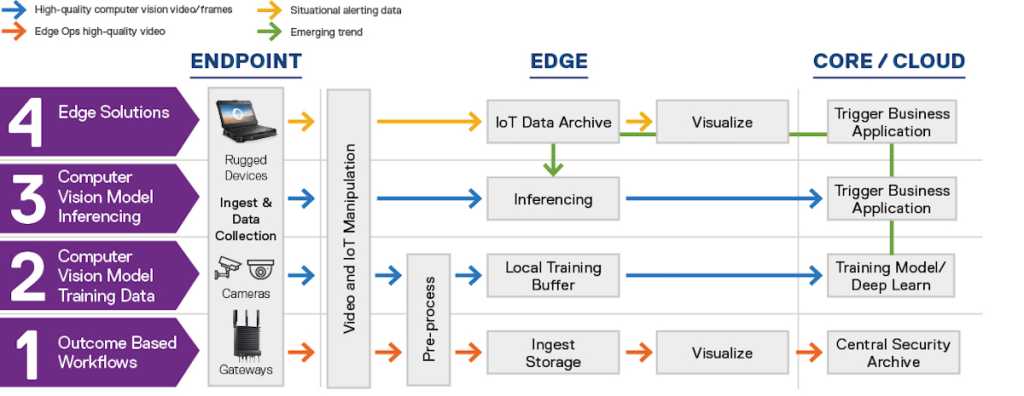

A extremely scalable laptop imaginative and prescient platform would allow you to mix and mixture the info, after which analyze the ensuing knowledge set to find out the reason for the off-spec product. Taking {that a} step additional—with a pc imaginative and prescient platform leveraging a federated strategy—the evaluation occurs in close to actual time as there could be no have to push giant quantities of knowledge again to a central storage location. This strategy makes use of fashions on the edge to research knowledge, sending solely the outcomes again to the central location for coaching and additional refinement of the mannequin (Determine 1). Then, solely the up to date mannequin is distributed again to the sting. It’s a way more environment friendly methodology of exactly and quickly figuring out whether or not some piece of apparatus or an element is operating a bit slower or a bit hotter versus performing bodily inspections.

Dell

Determine 1. Transferring to real-time situational consciousness and insights. An instance of a pc imaginative and prescient workflow the place knowledge seize, curation, motion, pre-processing, safety archiving, knowledge coaching and inferencing present real-time insights on the edge.

Different makes use of for laptop imaginative and prescient embrace the flexibility to discern colours within the high quality management course of (is the potato chip an ideal mild gold shade or brown and overcooked?) and to seek out defects in elements which might be troublesome to view inside bigger assemblies. Thermography can gauge the degrees of product in a tank, whether or not the product is crude oil within the area or soup in a manufacturing unit, in addition to the temperature of these tanks.

Trying to the longer term, predictive upkeep might be enhanced by laptop imaginative and prescient expertise, particularly for tools that must be in fixed movement, shortening the time-frame for replacements as a result of scheduling could be performed forward of time and decreasing general prices for upkeep. Laptop imaginative and prescient will have the ability to seize much more attributes from photographs and video, probably changing many sensors and transmitters used right now. Additionally count on to see complete factories designed nearly, making a digital twin with operating processes that may be optimized earlier than implementation.

3. How can we positively influence the worker or “individuals” expertise?

Sooner or later, count on vital enhancements to workday processes that at present require guide involvement and evaluation. As an worker enters a manufacturing unit, laptop imaginative and prescient might acknowledge that individual, recording the time they start a shift (no have to punch a timecard) and routinely unlock doorways to restricted areas. This additionally ties into security. In case of an emergency, plant managers and first responders may get instantaneous counts of the variety of individuals in numerous areas. And augmented actuality (AR) will allow rather more flexibility within the varieties of ability units required for sure jobs by pairing distant consultants with decrease expert employees sporting cameras and interacting by way of AR.

4. How can we have an effect on sustainability in manufacturing?

One desired end result of course of optimization is a discount in manufacturing consumption in relation to vitality, chemical utilization, air high quality and uncooked supplies. Does a motor have to run 24/7? Possibly not, and a pc imaginative and prescient platform can search for patterns to find out when that motor ought to run and when it may be idle, which impacts upkeep efforts and vitality utilization. The identical precept applies to chemical utilization, the place optimized utilization additionally means much less over- and under-dosing. And utilizing laptop imaginative and prescient manufacturing high quality reduces scrap that can not be reworked and results in landfills.

Cameras are additionally an environment friendly approach to monitor stack emissions as a part of an effort to cut back sulphur oxide (SOx) and nitrogen oxide (NOx) emissions, and to examine the colour of water, corresponding to in a reservoir, to find out the presence of pollution or algae.

5. How can we influence manufacturing income?

Enterprise homeowners have a look at ROI, NPV and different metrics to justify the financials for doing a undertaking or introducing a brand new product line. Laptop imaginative and prescient in manufacturing is used to extend income, cut back prices and improve employee security. For instance, maximizing first-pass high quality will increase yield or reduces scrap, saving cash in uncooked supplies. Furthering the sustainability dialogue, a discount in vitality or chemical utilization additionally decrease prices.

Though some facets of laptop imaginative and prescient have been in use in manufacturing for years, real-time knowledge analytics is having the most important influence. With extra vegetation embracing laptop imaginative and prescient for high quality assurance, plant visibility, tools monitoring and employee security, it’s potential to ascertain a world provide chain sooner or later that may higher react to exterior disturbance variables and proceed to function easily beneath virtually any circumstances.

For an summary of laptop imaginative and prescient and its influence on manufacturing, see Delivering game-changing Manufacturing High quality with Laptop Imaginative and prescient.

Be taught extra about how laptop imaginative and prescient is positively impacting different industries:

***

Intel® Applied sciences Transfer Analytics Ahead

Information analytics is the important thing to unlocking essentially the most worth you may extract from knowledge throughout your group. To create a productive, cost-effective analytics technique that will get outcomes, you want excessive efficiency {hardware} that’s optimized to work with the software program you utilize.

Trendy knowledge analytics spans a spread of applied sciences, from devoted analytics platforms and databases to deep studying and synthetic intelligence (AI). Simply beginning out with analytics? Able to evolve your analytics technique or enhance your knowledge high quality? There’s at all times room to develop, and Intel is able to assist. With a deep ecosystem of analytics applied sciences and companions, Intel accelerates the efforts of knowledge scientists, analysts, and builders in each trade. Discover out extra about Intel superior analytics.